Short-term electricity costs are expected to continue to increase globally due to the costs associated with investments in renewables as well as increases in the prices of commodities such as coal, oil and gas (with some exceptions in the short term regarding shale gas resources). In South Africa, price increases are driven by these issues along with a massive investment programme by the national power utility, Eskom, which includes coal-fired and nuclear options as well as some peaking capacity. Electricity users in South Africa have experienced a doubling in electricity prices over the last 3 years. Indications are that double-digit increases will continue, albeit at a somewhat reduced level. The implications are that any previously considered investments regarding power savings should be regularly reviewed by users, since their viability will continue to improve.

Given this context, energy-intensive industrial organisations around the world cannot afford to be without a meaningful plan to reduce electricity costs. This post will address what can be done to reduce peak demand charges, typically a significant cost for industrial operations.

Given this context, energy-intensive industrial organisations around the world cannot afford to be without a meaningful plan to reduce electricity costs. This post will address what can be done to reduce peak demand charges, typically a significant cost for industrial operations.

Electricity bills typically comprise a number of different elements, with the two major ones being charges for the quantity of energy consumed in the billing period (measured in kWh) and charges for peak demand (measured in kVA). Tariff structures can vary widely, depending on user size, location and other determinants. For energy consumption, either a flat rate is applied or users could be billed according to “time-of-use” charges, which vary the rate based on the time of day during which the energy is consumed and/or the time of year. Variable rate schemes are designed to change behaviour such that the installed power generation base can be optimally employed and maintained.

In the case of peak demand (also called "maximum demand") charges, a flat or variable rate is typically charged for each unit of apparent power consumed, based on the highest apparent power demanded in the billing period. Demand is monitored over defined intervals (for example time buckets of 15 minutes) to arrive at the peak demand level for which a site is billed. This billing strategy is generally applied during periods of peak electricity consumption. Hence weekends could be omitted, as could periods from 10p.m. until 6a.m. during weekdays. You will need to review your own tariff scheme and respond to that when trying to reduce your bills.

The 3 basic strategies that electricity users can employ to reduce peak demand charges are load shifting, power factor correction and the implementation of energy efficiency measures.

Load shifting

Electricity users can schedule high-demand processes such that they do not operate together, thereby reducing the overall peak for the site. Some processes may also be operated during periods in which peak demand charges do not apply. In planning such a strategy, one has to be mindful of the costs involved. For example, there may be overtime costs payable if plant operators are required to work outside of normal working hours in order to operate part of the plant. Of course, the needs of your customers will also drive the applicability of this approach, since it may conflict with your goals regarding the reliable supply of product.

This strategy, while it does have some application in industry, is difficult to apply in large continuous operations and is more suitable to batch-type operations or operations where short continuous runs are possible. For example, a site may have a number of production lines, all of which may not need to run at the same time. It is generally also true that where individual lines have significant excess capacity, the strategy is more easily executed. It is very useful to have a flexible labour force with plant operators who are capable of operating different production units when trying to implement load shifting, since this helps to prevent a situation developing where workers are idle.

Use of Power factor Correction

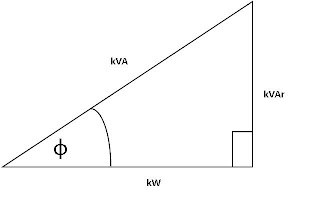

Power factor correction is a widely-accepted technological approach used to reduce peak demand. In order to explore this further, we need to review some basic theory regarding power and typical AC circuits. In AC circuits, voltage and current follow sinusoidal patterns. When voltage and current waveforms peak and trough at exactly the same point the waveforms are said to be “in phase”. Inductive and capacitive loads in a circuit can however cause these waveforms to become “out of phase”, with inductance causing the voltage to lead the current and capacitance causing the current to lead the voltage. The angle by which these waveforms are out of phase is known as the phase angle (ф). Power factor correction tries to get voltage and current back into phase in circuits which have an inductive nature by introducing additional capacitance.

Inductive loads such as motors, electromagnetic ballasts in light fittings, induction furnaces, transformers and the like are common on industrial sites, and tend to increases the amount of apparent power required. The bigger the difference between the apparent power (measured in kVA) and the real power (measured in kW) consumed, the lower a site’s power factor (Power factor = kW/kVA) at any instant in time and the higher the peak demand charges the site would have to pay. Note that what is important here is the power factor at peak demand, since a low power factor at low demand levels will not have an impact on demand charges. If the amount of apparent power can be reduced, peak demand can be reduced without any change in real power consumed.

Apparent power is the vector sum of real power (in kW) and reactive power (in kVAr).

Power factor = Real power / Apparent power = kW/kVA = cosф.

When kW = kVA, power factor = 1, ф = 0 and hence kVAr = 0. In order to improve power factor, a quantity of capacitance that will reduce the reactive power to a level corresponding to the desired power factor is required. Capacitance and inductance offset each other directly.

Example:

A site has a measured power factor of 0.8 at a peak demand level of 700 kVA. Calculate the amount of capacitance required to achieve a power factor of 0.98.

Since PF = 0.8, the real power consumed = 0.8 x 700 = 560 kW

Apparent power2 = Real power2 + Reactive power2

Reactive power = Square Root (Apparent Power2 – Real Power2)

= Square Root (7002 – 5602)

= 420 kVAr at a power factor of 0.8

At a power factor of 0.98, the Apparent power “consumed” = 560 / 0.98 = 571.4 kVA

Reactive power = Square Root (571.42 – 5602)

= 113.7 kVAr at a power factor of 0.98

The net capacitance required to correct the power factor is therefore 420 kVAr – 113.7 kVAr = 306.3 kVAr.

Capacitors are typically arranged in banks downstream of the transformers through which power is delivered to the site, and are accompanied by devices such as harmonic filters and controllers which control the amount of capacitance applied.

Energy Efficiency

Improvements in energy efficiency can have a significant impact on peak demand, but the relationship between the two depends on the specifics of the efficiency intervention concerned. Energy efficiency implies a reduction in the quantity of real power consumed. It is however possible to reduce the amount of energy consumed by a process without impacting on peak demand. The point here is that peak demand is based on the maximum apparent power drawn over a limited period of time rather than the total amount of energy consumed.

Consider a heating element, for example. It may have a specific power rating, say 100 kW. When on, it will consume this quantity of power, and if it is on at the same time as other large loads, the peak demand for the site concerned may not change. The element may however be used for shorter periods (due to insulation of the equipment in which it is installed for example), reducing total energy consumption i.e. the total kWh consumed by the element will be lower, but not the kW consumed. For resistive components such as heating elements, apparent and real power are equal.

On the other hand, installation of a high-efficiency motor with a similar power factor to the standard-efficiency motor it has replaced will both reduce energy consumption and maximum demand (assuming the motor runs continuously, or during periods of peak demand).

In general my approach is to look at energy efficiency and reductions in peak demand separately, with any demand benefits accruing due to energy efficiency projects considered to be a bonus. An exception is where opportunities exist to fundamentally change a process through, for example, the elimination of unnecessary energy-intensive unit operations with large inductive loads.

No comments:

Post a Comment