|

| Resource Efficiency is one of the most powerful cost reduction strategies available to manufacturers |

Manufacturing

sites are generally thought of as having two major types of costs: Fixed Costs,

which tend to be largely independent of the level of production, and Variable Costs, which are intrinsic to each unit of production, and therefore tend to

increase or decrease in direct proportion to the level of production. Fixed

costs would entail costs such as rent, salaries, protective clothing and the

like. Variable costs would include the costs of raw materials, water, energy

and other resources.

This is the

traditional way in which costs are viewed. In reality, it is however not quite

so simple. For example, wage bills can vary with production as a result of

overtime. Operating staff use a certain amount of water (which can be considered to be fixed) each month for ablutions

and energy costs associated with lighting and administration also tend to be

fixed. Hence even costs that are commonly considered as variable costs do have a fixed component. As a result, it is not uncommon

for the unit costs of these resources to increase significantly at low levels

of production as the fixed components of these costs becomes a bigger

proportion of the total cost per unit. In the case of

resources, technology does however exist which we can use to engineer the fixed

components out to a large degree. A simple example would be the use of a variable

speed drive to control the speed of a screw compressor to allow it to vary capacity with demand.

If you have

worked in manufacturing for any length of time, you will have seen that

manufacturing plants tend to perform best when capacity is fully utilised, and

that it is at low levels of production that meeting cost budgets linked to the

level of production becomes most difficult. This is partly explained by the fact

that equipment and processing plants tend to operate more efficiently when

running at design capacity levels. The

second more obvious reason is that the fixed component of the cost is spread

over more units of production, diluting its contribution.

In practice, at

very high levels of production the variable and total cost curve could

experience a sharper rate of increase as the facility becomes strained under

throughput levels that exceed design levels. The unit cost curve could then

start to look something like the one illustrated below.

In economic times

like the ones we are experiencing now, cutting costs is a vital strategy if

businesses are to survive. Costs can be attacked from the perspective of both

the fixed and variable components of the total cost. Fixed costs are largely

comprised of salaries and wages, and while this is generally an area heavily

targeted for restructuring exercises, this does come at a moral cost as well as a

reduction in human capacity within organisations, not to mention the morale

impacts on those left behind. It would be naive to think that staff numbers

could be reduced with no impact on productivity, or without knock-on impacts on

variable costs. For example, losses in expertise and tacit knowledge could lead

to an increase in material usage.

The variable

cost elements in manufacturing tend to be largely in the area of resource

consumption. For example, each unit of production tends to require a given amount of raw

material. The energy required to transport and process these materials tends to

increase in proportion to production levels, as does the water needed. Of

course, the picture is made more complex by the needs of individual products,

and changes in the mix of these products over time. However, in general terms,

increased resource efficiency tends to result in reductions in variable costs.

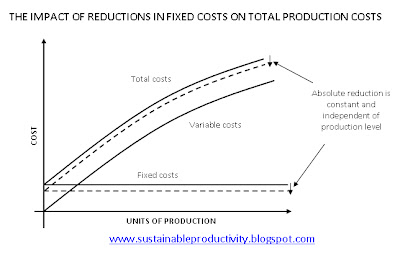

Let’s look for a

minute at how reductions in fixed and variable costs impact on the total costs

of production.

In the case of

fixed costs, absolute reductions are independent of the level of production.

Whether a site produces 100 units or 100,000 units, the quantum of the cost

saving will be the same, assuming of course that the fixed cost reduction has

no negative side effects. Hence the percentage reduction in costs per unit is

diluted as the level of production increases.

In the case of

variable cost reductions, an entirely different picture emerges. Since the cost

reduction is associated with each unit of production, the total value of the

savings realised increases with each additional unit of production. For

high-volume manufacturing operations, the benefits multiply quickly and can

have an enormous positive impact on the financial performance of the

enterprise.

How then are these variable cost reductions

realised? The following are the primary opportunities available to reduce

variable costs from a resource efficiency perspective. The examples outlined are energy-related, but the principles would apply to materials and water too:

- Optimise the existing plant through changes to process setpoints e.g. temperature and pressure settings

- Change work practices regarding plant operation to make the plant more efficient e.g. employing a de-fouling procedure to increase heat transfer rates across a piece of heat recovery equipment

- Improve plant maintenance practices, thereby reducing waste e.g. instituting a compressed air leak detection and maintenance programme

- Modify the plant to improve its efficiency e.g. installing a variable speed drive on a pump to save energy when flow is reduced, rather than incurring a pressure drop across a control valve

- Make significant technology investments to foster resource efficiency e.g. installing a condensing economiser on a gas-fired boiler to recover heat from flue gases

The significant

difference between these variable cost reduction options and fixed cost reduction options is that there

are typically no negative side effects to contend with. In the case of an

option like optimisation, since costs are negligible, the financial benefits

are profound, but this can also be the case for many opportunities requiring

capital investment. The biggest positive aspect of resource efficiency as a

cost reduction strategy is however the multiplier effect achieved due to its

focus on variable costs. And if you can find viable resource efficiency

projects in this economic climate when volumes in most manufacturing businesses

are depressed (and I know from experience that this is eminently possible),

imagine the impact on your bottom line when volumes pick up and that multiplier

effect magnifies the total savings achieved.

Copyright ©

2013, Craig van Wyk, all rights reserved